People usually ask friends to help move a couch, or load a truck with some boxes, but what if you need to relocate your warehouse? Consider your friends at Racked Out Inc.!

As exciting as moving into a new warehouse might sound, the least exciting part is moving out of your existing one. Everyone’s situation is different, but the results should be the same: pack, move, carry on.

We like to break down warehouse moves in a few steps:

- Tear down

- Shipping and Receiving

- Re-building

- PSR

Once the racks are clear of product, our team comes in to tear down the storage system. In our experience, proper material handling will go a long way to make the transition easier. Luckily, racking materials are quite symmetrical, making storage and handling easier if done correctly.

At this point, frames and beams can be evaluated for damage. Counterbalance forks are racking’s worst enemy, denting and bending the metal beyond repair. If frame damage is a common occurrence in your warehouse, check out our rack guards and protection.

When relocating, the amount of racking typically increases. In this case we could install new racking before you start the move. Installing the additional rack first enables you to move directly onto the new racking while we tear down your existing warehouse.

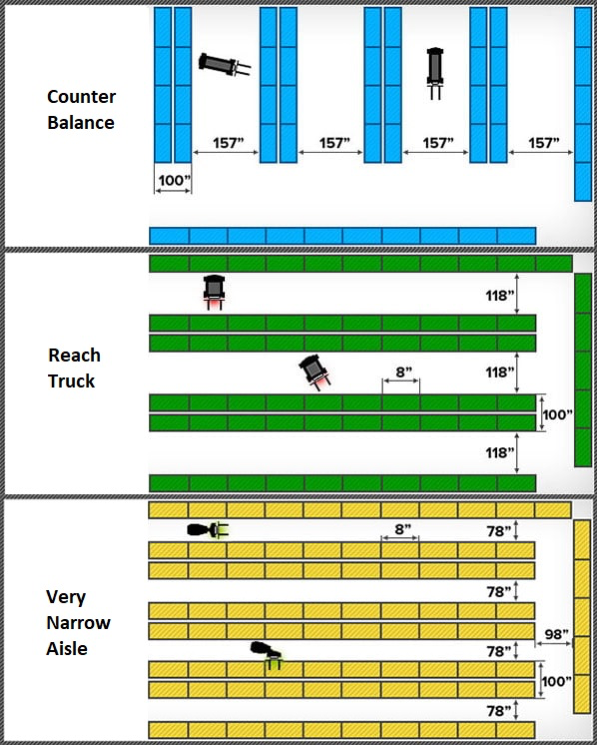

Relocating racks within the same warehouse can also help increase storage efficiency. As depicted below, the Very Narrow Aisles warehouse layout is a powerful trend to maximize space in your warehouse.

By investing in narrow aisle lift trucks, your warehouse can gain 55% more usable space than counter balance, and 30% more than Reach Truck. There isn’t any special racking needed; your current rack could be rearranged for VNA.

If your warehouse relocation project includes the tear-down of current racking systems, contact Racked Out Inc. to learn how our advanced systems can help save you time and money.