We Provide Comprehensive Pallet Racking Services in Canada

At Racked Out, we deliver complete warehouse storage solutions across Canada with a focus on safety, compliance, and operational efficiency. Our team of certified technicians brings decades of combined experience in pallet racking installation, maintenance, and repair to every project we undertake. We understand that your warehouse racking system is critical infrastructure. It supports your inventory, protects your workers, and directly impacts your ability to fulfill orders and serve customers effectively.

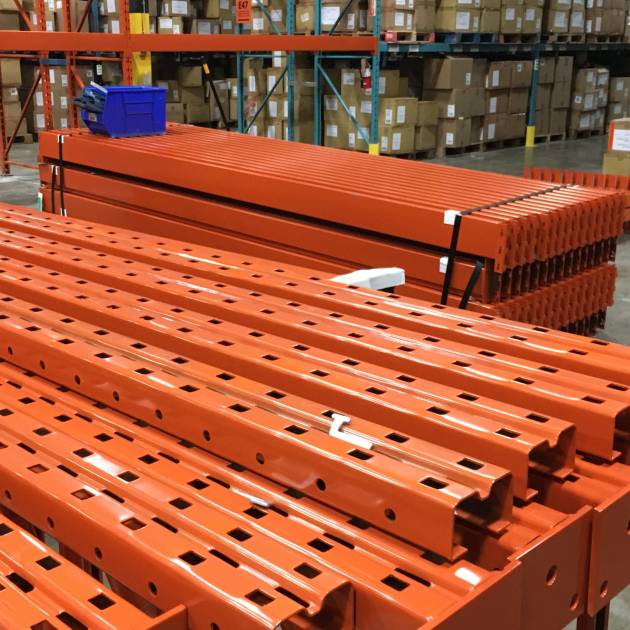

From initial installation to ongoing maintenance and emergency repairs, we provide the full spectrum of racking services that Canadian warehouse operators need. We work with all major racking brands including Ridg-U-Rak, Interlake, Speedrack, and Tier-Rack, ensuring compatibility whether you’re installing new systems or maintaining existing infrastructure. Our certified installers and inspectors stay current with CSA standards and industry best practices, giving you confidence that your racking system meets or exceeds all Canadian safety requirements.

Whether you’re expanding your facility, relocating operations, upgrading to higher capacity systems, or simply maintaining your existing racking, Racked Out delivers the expertise and service your business demands.

Racking Installation

Starting with solid foundations ensures long-term success. Our installation services create storage systems that maximize your warehouse capacity while meeting all safety and regulatory requirements. We handle complete projects from initial space planning through final inspection, delivering turnkey installations ready for immediate operation.

Complete System Design and Planning – We assess your facility dimensions, inventory characteristics, and operational workflow to design racking layouts that maximize storage density while maintaining safe working conditions. Our CAD drawings show exactly how your new system fits your space before we begin installation.

Expert Installation Execution – Our certified installation crews bring years of experience and professional-grade equipment to every project. We install all racking types including selective pallet racks, drive-in systems, cantilever racks, and specialized storage solutions. Proper installation following manufacturer specifications ensures your system performs safely from day one.

Safety-Compliant Construction – Every installation meets Canadian Standards Association requirements and provincial building codes. We anchor frames properly, install all safety components, verify structural alignment, and document compliance. You receive complete installation certification satisfying regulatory requirements and insurance obligations.

Racking Tear-Down

When you’re relocating, downsizing, or reconfiguring your warehouse space, professional racking tear-down protects your investment and ensures worker safety throughout the dismantling process. Our experienced crew carefully dismantles your pallet racking system using proper techniques that prevent component damage and maintain the structural integrity of beams, uprights, and hardware for future use. We understand that your racking represents a significant capital investment, and we treat every component with the care necessary to preserve its value whether you’re moving it to a new location or preparing it for resale.

We handle tear-down projects of any scope, from removing a few rows of selective racking to dismantling complete multi-level storage systems in facilities spanning hundreds of thousands of square feet. Our crew arrives with the proper tools and safety equipment to disconnect beam-to-upright connections, remove anchoring systems, and carefully lower components to ground level without damaging your facility floors, walls, or existing infrastructure. Safety is our top priority during every tear-down project. We establish exclusion zones, implement proper rigging techniques, and follow CSA safety protocols to protect our workers and your employees throughout the dismantling process.

Facility Safety Systems

Comprehensive facility safety systems protect your warehouse workers, inventory, and infrastructure from costly accidents that can shut down operations and create serious liability issues. At Rackedout.ca, we install and maintain column protectors, end-of-aisle guards, safety netting, rack-mounted barriers, and floor marking systems that meet CSA safety standards and create multiple layers of protection throughout your facility. These safety systems are not optional extras. They are essential investments that prevent forklift impacts from damaging your racking structure, stop falling products from injuring workers, and establish clearly defined traffic patterns that reduce collision risks.

Column protectors and end-of-aisle guards absorb and redirect the impact energy when forklifts accidentally strike your racking system. Without these protective barriers, even minor impacts can compromise upright integrity and create dangerous instability in your storage system. We install heavy-duty steel column guards that surround your most vulnerable uprights, particularly at corners and aisle ends where forklift traffic is heaviest. These guards can withstand repeated impacts without transferring damaging force to your racking structure, significantly extending the lifespan of your storage system and reducing repair costs. We also install bollards and protective barriers that keep forklifts at safe distances from your racking, creating physical boundaries that prevent contact altogether.

Rack Maintenance Programs

Regular rack maintenance programs extend the life of your storage system and maintain CSA compliance year after year, protecting your business from safety violations and catastrophic failures. At Rackedout.ca, our scheduled inspections identify damaged components, loose connections, and safety concerns before they become serious problems that threaten your workers or inventory. Most warehouse operators lack the specialized knowledge to recognize early warning signs of racking failure, such as beam deflection, anchor bolt loosening, or upright twist. Our certified inspectors bring trained eyes and measurement tools to every inspection, evaluating your racking system against CSA A344.2 standards and manufacturer load specifications.

We recommend quarterly or semi-annual inspections depending on your facility’s forklift traffic levels, load weights, and operating conditions. High-volume warehouses with constant forklift activity benefit from quarterly inspections that catch damage early, while lower-volume facilities may maintain adequate safety with semi-annual inspections. During each visit, our inspectors systematically examine every aisle and bay, checking upright plumbness, beam engagement, anchor integrity, and component damage. We photograph any issues we discover and document their location within your facility, creating detailed inspection reports that clearly explain what we found and what actions you need to take. These reports satisfy workplace safety requirements and provide clear evidence of your compliance efforts if regulatory inspectors visit your facility.

Damage Repair & Component Replacement

Warehouse racking damage from forklift impacts, overloading, or normal wear requires immediate professional attention to prevent partial or complete system failure. At Rackedout.ca, we provide emergency repair services and scheduled component replacement that restores your racking system to safe operating condition quickly. Even minor damage to racking uprights, beams, or bracing can significantly reduce load capacity and create serious safety hazards. A bent upright loses structural strength, a damaged beam cannot support its rated capacity, and compromised bracing allows frames to twist under load. Our repair technicians assess the severity of every damaged component and determine whether repair or replacement is the appropriate solution.

We stock a comprehensive inventory of replacement uprights, beams, bracing, anchor bolts, and hardware compatible with all major racking brands including Ridg-U-Rak, Interlake, Speedrack, Tier-Rack, and others. This extensive parts inventory allows us to complete most repairs immediately without waiting for special orders or manufacturer deliveries that could keep sections of your warehouse out of service for weeks. When we replace damaged components, we match manufacturer specifications exactly, ensuring your repaired racking maintains its original load ratings and structural integrity. Our technicians use proper installation techniques including verified beam engagement, torqued anchor bolts, and plumb upright alignment. Every repair meets the same quality standards we apply to new installations.

Pre-Start Safety Inspection

Pre-start safety inspections ensure your new or relocated racking system meets all CSA requirements before you begin loading inventory and operating forklifts in your warehouse. At Rackedout.ca, our certified inspectors verify proper installation, check load capacities, confirm anchor integrity, and document compliance with Canadian safety standards before you put a single pallet on your racks. This critical inspection process protects your business from liability and ensures your workers are operating in a safe environment from day one. Many warehouse operators assume that new racking installations are automatically compliant, but installation errors, improper anchoring, and incorrect configuration can create serious hazards that are not visible to untrained observers.

Our pre-start inspection process follows CSA A344.2 guidelines and includes comprehensive evaluation of every critical safety element. We verify that all uprights are properly plumb and anchored to your concrete floor with appropriate anchor types for your specific floor conditions. We check every beam connection to ensure connectors are fully engaged and safety clips are properly installed. We measure aisle widths to confirm adequate clearance for your forklift equipment. We verify that your racking configuration matches engineered drawings and that load capacities are appropriate for the products you plan to store. We inspect bracing connections, base plates, shims, and column protectors. Every element that contributes to racking stability and safety receives careful examination and documentation.

Labelling

Proper rack labelling is a CSA requirement that prevents overloading and ensures safe operation throughout the life of your storage system. At Rackedout.ca, we provide and install durable capacity placards that clearly display maximum load ratings for beams and uprights in both metric and imperial measurements. These labels are not suggestions or guidelines. They represent the engineered load limits that your racking system can support safely, and exceeding these limits can cause catastrophic failures that collapse racks, destroy inventory, and injure or kill workers. Every warehouse operator has a legal obligation to display accurate load capacity information and train workers to follow these limits strictly.

Our capacity placards use weatherproof materials and industrial-grade adhesives that remain legible for years despite exposure to dust, temperature changes, and the harsh conditions common in warehouse environments. We install labels at eye level on the front of each racking bay where forklift operators can easily see them before loading. Each placard displays the maximum load per beam level, maximum load per bay, and maximum load per upright frame, giving your team complete information to make safe loading decisions. We also include the date of installation and inspection information that helps track your maintenance schedule. For facilities storing products with varying weights, clear labeling prevents workers from inadvertently overloading sections of racking with heavier items that exceed design capacity.